Dealing with Sticky Grease: Cleaning and Lubrication Techniques

One of the most common challenges encountered when repairing antique phonographs is dealing with old, hardened grease. Over decades, this grease degrades, becoming sticky, gummy, and impeding the smooth operation of your machine's intricate mechanisms. This article will guide you through the safe and effective removal of old grease and the application of appropriate lubricants to restore your phonograph to its former glory.

Understanding the Problem: Why Grease Turns Bad

Originally, phonograph manufacturers used grease to dampen vibrations and reduce friction within the drive system, escapement, and other moving parts. These greases, often based on mineral oils or animal fats, naturally degrade over time. Exposure to air, temperature fluctuations, and contamination can cause them to oxidize, harden, and become incredibly resistant to movement. This stickiness leads to sluggish performance, increased wear, and can even damage delicate components. Understanding the underlying cause of this degradation is key to choosing the correct cleaning and lubrication approach – a subject explored in more detail in resources like Understanding and Troubleshooting the Governor Mechanism in Phonographs, which delves into the crucial role of the governor and its susceptibility to grease build-up.

Safe Grease Removal Techniques

Aggressive methods like scraping with sharp tools can easily damage surrounding parts. A more patient and methodical approach is crucial. Here's a breakdown of effective techniques:

- Solvent Cleaning: This is the primary method. Several solvents can be used, each with its pros and cons:

- Mineral Spirits: Relatively mild, readily available, and generally safe for most phonograph components. It’s a good starting point.

- Isopropyl Alcohol (IPA): A stronger solvent than mineral spirits, effective for dissolving stubborn residue. Use cautiously, as it can potentially affect some finishes. 91% or higher concentration is recommended.

- Citrus-Based Cleaners: Environmentally friendly, but test a small, inconspicuous area first, as they can sometimes react with certain materials.

- Application Methods: The key is targeted application.

- Cotton Swabs: Perfect for small, precise areas.

- Soft Brushes: Help loosen the grease and push it into the solvent.

- Syringe/Dropper: For controlled delivery of solvent to hard-to-reach areas.

- Important Precautions:

- Ventilation: Always work in a well-ventilated area.

- Gloves: Protect your hands.

- Mask: Consider a respirator, especially when using stronger solvents.

- Material Compatibility: Test the solvent on a hidden area before widespread use.

- Grease vs. Oil: Grease is thicker and stays in place better, ideal for slow-moving gears and points of high friction. Oil is thinner and flows more easily, suitable for lighter moving parts.

- Recommended Lubricants:

- Lithium Grease: A good all-around choice for gears and bearings.

- Silicone Grease: Resistant to heat and doesn't attack rubber or plastic parts.

- Sewing Machine Oil: A lightweight oil suitable for escapements and other delicate mechanisms.

- Application Techniques:

- Apply sparingly! A tiny amount goes a long way.

- Use a needle or pipette for precise placement.

- Work the lubricant into the moving parts to ensure even distribution.

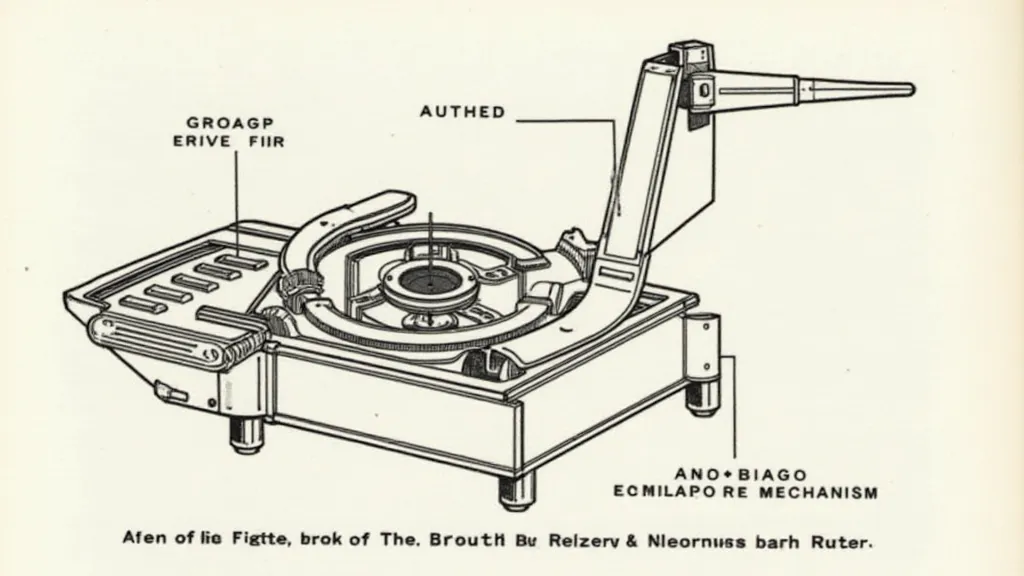

- Drive System: The motor, springs, and transmission gears are crucial for playback speed.

- Escapement Mechanism: This controls the speed of the record's rotation.

- Tone Arm Bearings: Ensuring smooth tracking.

- Spindle Bearing: Often overlooked, but essential for stable record rotation.

- Slow or Erratic Playback Speed: This frequently indicates issues with the drive system. The motor may be struggling to overcome the resistance of hardened grease. Thorough cleaning of the motor bearings and gear train is paramount.

- Record Skipping or Tracking Problems: The tone arm is particularly susceptible to problems caused by sticky grease. Insufficient lubrication in the tone arm bearings can lead to erratic tracking and skipping.

- Governor Malfunctions: The governor, a vital component for maintaining consistent playback speed, is also commonly affected. Issues with the governor are described in more detail in Troubleshooting a Sticking Phonograph Governor: Causes, Diagnosis, and Solutions.

- Excessive Noise: Hardened grease can create friction and squeaking sounds as the phonograph operates. This is a clear indication that cleaning is needed.

- Periodic Cleaning: Lightly dusting the phonograph and carefully wiping down moving parts can prevent the accumulation of dirt and grime.

- Annual Lubrication: Reapplying a thin layer of appropriate lubricant once a year can keep moving parts operating smoothly.

- Proper Storage: When not in use, store the phonograph in a clean, dry environment, away from direct sunlight and extreme temperatures.

- Considering the Historical Context: Recognizing the historical significance of your phonograph, and understanding the original materials and construction techniques, further contributes to responsible restoration and long-term preservation. Learning about the cultural landscape that shaped these machines allows for a deeper appreciation of their value and importance. Resources delving into the history of phonographs, like Echoes in Amber: Restoring the Ghosts of Parlor Music, provide valuable context and insights.

Lubrication: Choosing the Right Grease and Oil

Once the old grease is removed, it's essential to apply the correct type of lubricant. Using the wrong lubricant can be as detrimental as using old grease. Selecting the appropriate lubricant is also deeply connected to how the phonograph's mechanisms are designed and function, a subject that frequently intersects with understanding the specific model you are working on. For example, restoration efforts on an Edison Standard Phonograph Mechanism require a nuanced understanding of lubrication points and types.

Specific Areas to Focus On

While the entire mechanism may benefit from attention, certain areas are particularly prone to grease build-up:

Troubleshooting Common Issues Arising from Sticky Grease

Beyond the basic cleaning and lubrication, sticky grease often manifests in more complex operational problems. Recognizing these symptoms and understanding their root cause is a crucial part of the restoration process.

Preservation and Long-Term Care

After a successful cleaning and lubrication, preserving the condition of your antique phonograph is key. Regular maintenance can prevent the return of sticky grease and prolong the life of your machine.

Final Thoughts

Dealing with sticky grease is an integral part of restoring antique phonographs. Patience and attention to detail are key. By employing careful cleaning and lubrication techniques, you can breathe new life into these beautiful machines and ensure their continued enjoyment for years to come.