Understanding and Troubleshooting the Governor Mechanism in Phonographs

The governor mechanism is a vital, and often misunderstood, component in antique phonographs. Its primary function is to regulate the turntable speed, ensuring accurate playback of records. Without a properly functioning governor, your phonograph will play at inconsistent speeds, resulting in a distorted and unpleasant listening experience. This article will delve into the workings of the governor, common issues encountered, and troubleshooting techniques to restore proper speed regulation.

How the Governor Works

At its core, the governor is a speed-sensitive device. In most phonographs, this takes the form of a rotating flywheel with weighted arms, commonly referred to as “flyweights.” As the turntable spins, the flyweights are forced outwards by centrifugal force. The extent to which they extend dictates the amount of friction applied to the driving motor.

Let's break down the process:

- Turntable Speed Increases: When the turntable spins faster, the flyweights extend further. This increased extension puts more friction on the motor, slowing it down.

- Turntable Speed Decreases: Conversely, if the turntable slows down, the flyweights retract, reducing friction and allowing the motor to spin faster, attempting to compensate for the loss of speed.

This constant adjustment creates a feedback loop, striving to maintain a consistent turntable speed regardless of variations in motor speed or load. The complexity of achieving consistent speed regulation in these machines is fascinating; for those deeply interested in the broader picture, exploring understanding the speed regulation system in antique phonographs can provide even more context.

The level of friction is typically adjusted through a screw or lever, allowing the user to fine-tune the playback speed. However, this adjustment is only effective if the governor mechanism itself is operating freely and accurately.

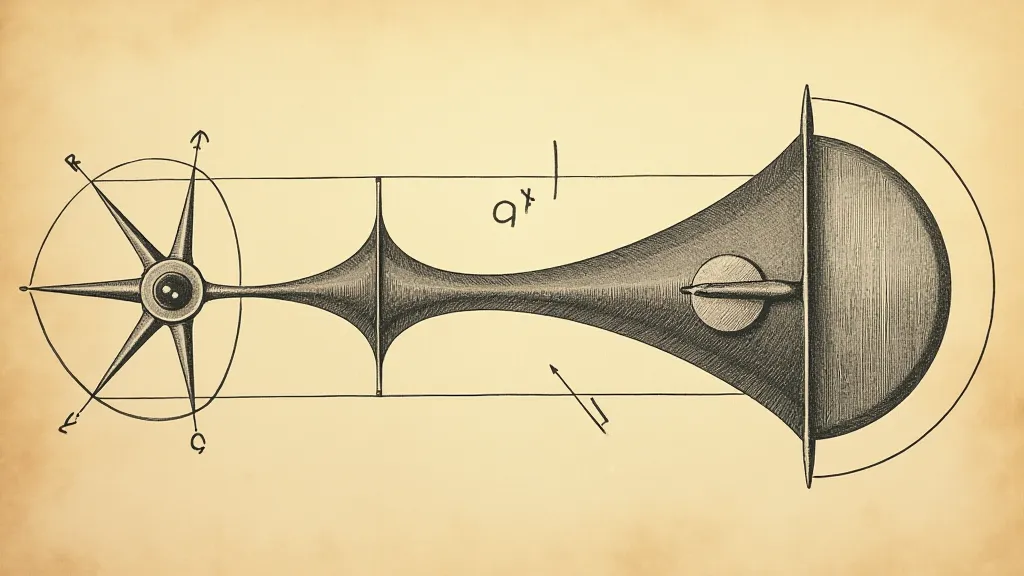

Image 1: A close-up photograph of a typical phonograph governor mechanism, showing the flywheel and weighted arms. The mechanism is partially disassembled, allowing clear visibility of its components.

Common Problems and Troubleshooting

Several issues can prevent the governor from operating correctly. Identifying and resolving these problems is crucial for restoring proper playback speed. Before embarking on any repairs, it’s important to recognize the challenges inherent in working with these delicate machines. Often, the entire playback quality hinges on more than just the governor; issues with the drive mechanism itself can significantly impact performance. Dealing with a noisy phonograph, for instance, can often lead back to underlying problems with the motor or other moving parts.

- Sticking or Binding Flyweights: This is perhaps the most common issue. Years of accumulated dust, grease, and grime can cause the flyweights to stick, preventing them from responding accurately to changes in speed.

- Worn or Damaged Springs: The springs that control the flyweight movement can weaken or break over time. This will affect the responsiveness of the governor.

- Incorrect Governor Adjustment: While not a mechanical failure, an improperly adjusted governor can result in incorrect speed.

- Binding Governor Lever: The lever that connects the governor to the motor can become stiff or bind, hindering its ability to regulate speed.

- Broken or Bent Governor Arms: Damage to the arms themselves can disrupt the governor's action, affecting the accuracy of speed regulation. Replacement can be difficult, and the condition of other parts, like the cabinet, may also reveal the machine's overall history.

Solution: These parts are very delicate and usually require replacement. Finding replacement arms might be challenging. Precise alignment and proper balance are necessary if replacing the arms.

Solution: Carefully clean the flyweights and their pivot points with a solvent specifically designed for delicate mechanisms (e.g., naphtha or isopropyl alcohol). A fine brush is essential to reach all areas. Ensure the pivots are completely free of obstructions.

Solution: If a spring is visibly damaged, it needs to be replaced. Matching the original spring’s specifications is critical to maintain proper function. Obtaining replacements can be challenging and may require searching specialty suppliers.

Solution: Use a strobe light to accurately measure the turntable speed. Adjust the governor's friction screw until the correct speed is achieved. Small adjustments make a big difference, so be patient and precise.

Solution: Check for any corrosion or debris obstructing the lever’s movement. Lubricate the pivot points with a light machine oil, being careful not to apply too much.

The careful preservation of these machines isn’t just about mechanical repair; it's also about maintaining the aesthetic beauty. Sometimes the condition of the cabinet is a significant factor in the machine’s value and overall charm; considering the art of cabinet restoration can offer valuable insights into preserving the machine's beauty and historical significance.

Image 2: A diagram illustrating the relationship between the turntable speed, the flyweight extension, and the motor friction. The diagram visually shows how the governor responds to changes in speed.

Restoration Tips

When restoring a phonograph governor, it’s vital to proceed carefully. The components are often fragile and easily damaged. Avoid applying excessive force or using harsh chemicals. Beyond the governor itself, numerous other components contribute to the overall functionality. If you are experiencing an issue, it’s often a good idea to systematically investigate all connected systems.

- Documentation: Before disassembling the governor, take photographs and make detailed notes of the component arrangement. This will simplify reassembly.

- Gentle Cleaning: Use a fine brush and solvent to gently remove dirt and grime.

- Proper Lubrication: Apply a light machine oil to the pivot points. Avoid using excessive lubrication, which can attract more dirt.

- Patience: Reassembling the governor can be intricate. Take your time and double-check your work.

The nuances of these mechanisms often necessitate understanding the specific model you're working with. For example, the intricacies of the Edison Standard Phonograph differ considerably from those of other models. Understanding the Edison Standard phonograph mechanism provides a deeper appreciation for the range of design and engineering approaches employed in these historic devices.

Image 2: A photograph showcasing a phonograph governor mechanism after a complete restoration. The mechanism is clean, well-lubricated, and appears to be operating smoothly. The photograph evokes a sense of careful craftsmanship.

Advanced Considerations

Beyond the basic troubleshooting steps, a comprehensive understanding of the phonograph's overall design is invaluable. The entire interplay of mechanical and electrical components contributes to the final sound quality. The complexity can be daunting, and resources like detailed schematics and service manuals are often essential for successful restoration. Furthermore, the availability of parts can be a significant challenge. Specialized suppliers and online communities are often the best source for hard-to-find components. The continued existence of these machines is testament to the ingenuity and craftsmanship of their original creators, but it also relies on the dedication of enthusiasts who are committed to preserving this legacy.

Conclusion

The governor mechanism is a critical element in a phonograph’s ability to produce accurate and enjoyable sound. Understanding its function and diligently addressing common problems can dramatically improve playback performance. With careful attention to detail and a methodical approach, you can restore your antique phonograph to its former glory, enjoying the timeless charm of vintage audio. Mastering these skills is a rewarding endeavor, connecting you to a rich history of technological innovation and artistic expression.