Repairing the Brake Mechanism on Antique Phonographs

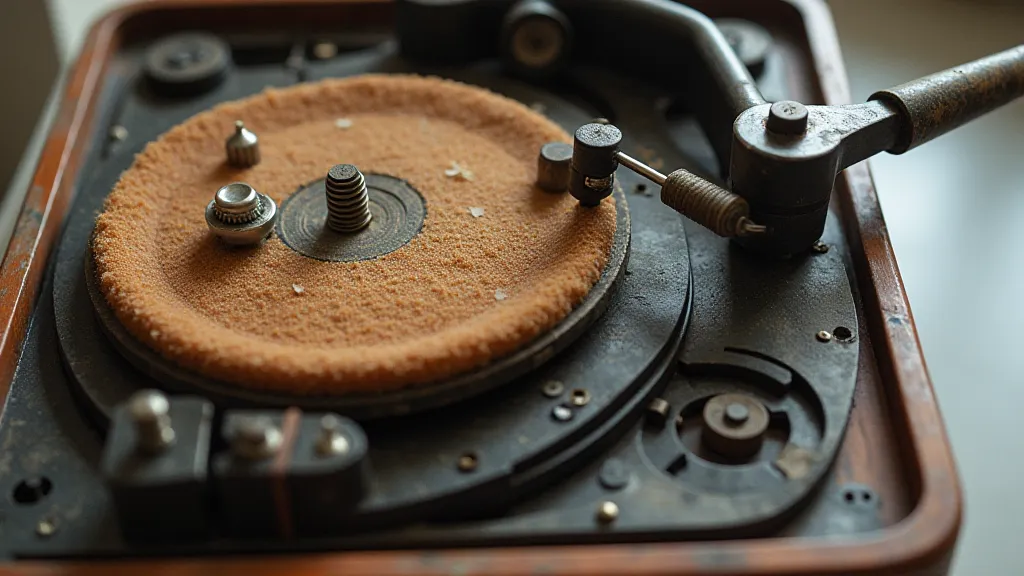

The brake mechanism on an antique phonograph is a surprisingly vital component. It's responsible for maintaining consistent speed during playback, preventing the turntable from overrunning, and contributing to overall sound quality. A malfunctioning brake can lead to speed inconsistencies, warped records, and frustration. This guide will help you diagnose and repair common issues with the brake mechanism on your vintage phonograph.

Understanding the Brake Mechanism

Before diving into repairs, let’s understand how a phonograph brake typically functions. Most antique phonographs use a friction brake – a pad or felt pressure against the running turntable. This pressure is controlled by a lever or spring system. The amount of pressure and its precise placement are key to proper operation. Different models have variations, so familiarity with your specific phonograph’s design is essential. Inspecting the brake's physical construction is always the first step.

Understanding the Larger System: Speed Regulation

The brake's function isn't isolated; it’s part of a larger, carefully engineered system designed to maintain accurate speed. The concept of speed regulation in antique phonographs is fascinating, and understanding the principles behind it can provide invaluable insight when troubleshooting issues, including brake problems. The speed regulation system is designed to overcome variations in motor speed and power fluctuations. You can learn more about the intricacies of understanding the speed regulation system in antique phonographs, which will help you appreciate the crucial role the brake plays in this process. The delicate dance between the motor, the drive system, and the brake is a testament to the ingenuity of early audio engineering.

Common Brake Mechanism Problems

Let's cover some common problems encountered with antique phonograph brakes:

- Worn or Contaminated Brake Pad: This is the most frequent issue. The felt pad loses its effectiveness over time, becoming hardened, compressed, or accumulating dust and grime.

- Sticking Lever: The lever that applies pressure to the brake pad might be sticking due to rust, dried lubrication, or mechanical binding.

- Broken or Weak Spring: The spring responsible for applying tension on the lever might be broken or weakened, resulting in insufficient braking force.

- Misalignment: The brake pad may be misaligned, failing to make consistent contact with the turntable's edge.

- Rust and Corrosion: Rust can immobilize the entire brake system.

- Motor Speed Fluctuations: Sometimes, the underlying problem isn't the brake itself but the motor providing the drive. Variations in motor speed can place undue stress on the brake system and accelerate wear.

- Internal Component Wear: As with any mechanical device of this age, internal wear of bushings and bearings within the brake assembly can also cause issues, leading to inconsistent pressure and erratic speed.

Diagnosis - Identifying the Issue

Begin by carefully observing the brake’s action during playback. Is the speed erratic? Does the turntable slow down noticeably after a record ends? Does the brake pad appear to be contacting the turntable properly? A visual inspection under good light is critical. Consider these steps:

- Visual Inspection: Examine the brake pad for wear, contamination, and damage.

- Manual Test: With the phonograph unplugged, manually rotate the turntable. Feel for any resistance from the brake. Listen for any squeaks or grinding noises.

- Playback Test: (Always exercise caution!) Listen for speed fluctuations while a record is playing.

- Motor Assessment: Observe the motor’s behavior. Does it sound smooth and consistent, or does it exhibit any unusual noises or vibrations? This can offer clues about potential issues impacting the brake’s function.

- Component Play: Carefully check the free play of all components of the brake mechanism. Excessive slop can indicate worn parts and contribute to inconsistent performance.

Repair Procedures

Once you're confident in your diagnosis, here are repair steps to consider:

- Cleaning: Use a soft brush and solvent (denatured alcohol works well) to clean the brake pad and the surrounding mechanism. Be careful not to damage delicate parts.

- Brake Pad Replacement: This is often the easiest fix. Purchase a replacement felt pad (available from vintage audio suppliers) and secure it in place according to the original design. Avoid using overly thick or stiff pads.

- Lever Lubrication: Apply a small amount of light machine oil to the lever pivot points to free up any sticking.

- Spring Replacement: If the spring is broken or visibly weak, replace it with an identical spring. Accurate spring strength is important for proper function.

- Alignment Adjustment: If the brake pad is misaligned, carefully adjust its position until it makes consistent contact with the turntable.

- Rust Removal: For heavy rust, use a rust remover specifically formulated for delicate mechanical parts.

- Component Sourcing: Finding the right replacement parts can be a challenge. Fortunately, several resources cater specifically to antique phonograph enthusiasts. If you are having trouble, finding replacement parts for antique phonographs can provide a starting point. Many of these suppliers also offer detailed diagrams and exploded views of various phonograph models, which can be invaluable when attempting repairs.

- Record Maintenance: While primarily focused on the mechanism, remember that the condition of your records themselves can influence the perceived performance. Dirty or damaged records can place extra strain on the drive system. Regular cleaning and preserving antique phonograph records is crucial for both sound quality and the longevity of your machine.

The Broader Context: Social Impact and Technological Significance

Repairing antique phonographs isn't just about fixing a piece of machinery; it's about preserving a piece of history. These machines played a significant role in the social fabric of early 20th-century society, influencing music distribution, entertainment, and even social gatherings. Understanding the nuanced workings within these machines, from the motor’s operation to the precision of the brake, highlights the brilliance of the era’s engineering. The intricacies of these machines are beautifully documented in articles that delve into the intricacies of their mechanics. Consider exploring “The Cartographer of Silence: Mapping the Internal Landscapes of Record Players” for a deeper dive into these internal mechanisms.

Important Considerations

Repairing the brake mechanism requires patience and attention to detail. Here are a few crucial reminders:

- Documentation: Take photos or draw diagrams before disassembling anything. This helps with reassembly.

- Gentle Handling: Antique phonograph parts are often fragile. Handle them with care.

- Proper Lubrication: Use the correct type of lubricant for mechanical parts. Avoid excessive lubrication.

- Safety First: Always unplug the phonograph before attempting any repairs.

- Electrical Safety: While this guide focuses on the mechanical brake, remember that antique phonographs often contain electrical components. If you are unfamiliar with electrical repair, seek assistance from a qualified technician.

- Long-Term Preservation: Consider the long-term effects of your repairs. Using archival-quality lubricants and replacement parts can help ensure the longevity of your antique phonograph.

- Understanding Edison Systems: If you own an Edison Standard Phonograph, the complexities of its mechanism are even greater. Understanding “Understanding the Edison Standard Phonograph Mechanism” can provide valuable insights into the unique challenges and solutions associated with these iconic machines.

By following these steps, you can successfully repair the brake mechanism on your antique phonograph, restoring its ability to play records at the correct speed and preserving a piece of audio history. Remember that these machines represent a remarkable achievement in engineering and design, and their continued operation requires dedication and a respect for their legacy.