Understanding the Speed Regulation System in Antique Phonographs

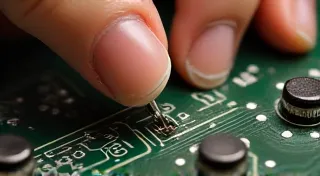

Maintaining accurate playback speed is crucial for enjoying antique phonographs. Early phonographs weren’t simply driven at a fixed speed; instead, they employed ingenious, albeit complex, speed regulation systems to compensate for variations in the motor’s power output and friction within the mechanism. Understanding how these systems worked, and the common issues that arise during restoration, is essential for anyone undertaking phonograph repair. The intricacies involved can sometimes feel overwhelming, and even seemingly simple tasks like correcting a corroded connection might require a little more knowledge - exploring soldering basics for phonograph repair can be a good starting point.

The Problem: Motor Variability and the Importance of Model Identification

The motors used in early phonographs (primarily induction motors and later, synchronous motors) weren’t consistent in their output. Factors like voltage fluctuations, wear on the motor windings, and even temperature could significantly impact the speed at which the turntable rotated. Without a mechanism to compensate, the playback would be either too fast or too slow, drastically affecting the fidelity of the reproduced sound. Furthermore, friction in the drive system (belts, gears, worm drives) increased with wear, further distorting the intended speed. Identifying the exact model and its inherent design characteristics is also paramount to understanding the intended speed regulation system—a visual guide to identifying different phonograph models can be incredibly helpful in this process. Knowing whether you are dealing with an Edison, a Victor, or a later model profoundly impacts the troubleshooting approach. For instance, the complex governor systems found in Edison machines demanded a markedly different skillset than the worm drive systems prevalent in Victor models.

The Mechanisms of Speed Regulation

Several different approaches were used to regulate speed, each with its own advantages and disadvantages. Let's examine some of the most common:

1. Governor Systems (Common in Edison Phonographs)

The Edison Standard and Home models are perhaps the most well-known examples of phonographs utilizing a governor system. These governors typically consisted of a weighted fly that rotated at a speed proportional to the motor’s speed. The fly's movement controlled a linkage that adjusted a friction brake applied to the motor's spindle. When the motor sped up, the fly moved outward, applying more friction and slowing it down. Conversely, if the motor slowed, the fly moved inward, reducing friction and allowing the motor to speed up. This feedback loop maintained a relatively constant speed. The design principles behind these governor systems are fascinating, and understanding them necessitates a meticulous examination of their components and their interplay.

The complexity of these governors is also their downfall. They are very sensitive to wear, and the delicate balance can be easily disrupted, leading to speed instability. Sometimes a seemingly minor issue like a sticking governor arm can throw off the whole system. Troubleshooting these issues effectively requires a methodical approach – consulting a dedicated guide to troubleshooting a sticking phonograph governor can provide a valuable step-by-step process. Beyond simple fixes, understanding the mechanical relationships between the fly, the brake, and the motor shaft is vital for accurate restoration.

2. Worm Drive Systems with Flyweight Compensation (Victor Phonographs)

Victor phonographs often employed worm drive mechanisms coupled with a less direct form of flyweight compensation. The worm gear provided a significant speed reduction, but inherent variability in the motor still needed to be addressed. While not as precise as the Edison governor, a weighted arm or flywheel attached to the turntable exerted a damping effect, helping to stabilize the speed. This was a simpler solution but offered less precise regulation. The combination of the worm gear and flywheel presented unique challenges in terms of wear and lubrication. Proper lubrication is key to extending the lifespan of these systems, and selecting the correct lubricant is paramount; using the incorrect type can lead to accelerated wear and damage.

3. Synchronous Motors and Governors (Later Models)

As technology advanced, synchronous motors became more common. These motors inherently operate at a speed directly tied to the frequency of the AC power supply. However, even synchronous motors could benefit from a simple governor to compensate for minor fluctuations or load variations. These later governors were often less elaborate than their Edison counterparts. The transition to synchronous motors represented a significant shift in phonograph design and maintenance practices, often demanding a reevaluation of restoration techniques.

Challenges in Maintaining Accurate Speed

Restoring the speed regulation system of an antique phonograph presents several challenges:

- Wear and Tear: Components are often worn, corroded, or broken. The governor arms, linkages, and friction surfaces are particularly susceptible to damage. This corrosion is especially common in areas where lubrication has dried out and metallic components are exposed.

- Lack of Lubrication: Dried-out grease or oil can seize up the mechanisms. Proper lubrication is crucial, but using the wrong type of lubricant can cause more harm than good.

- Incorrect Adjustment: Even if the mechanism is mechanically sound, incorrect adjustment can lead to speed instability. This often requires a very fine touch and a deep understanding of the governor’s intended operation.

- Component Replacement: Finding replacement parts for these complex systems can be difficult, requiring careful sourcing or fabrication of new components. This is frequently the most time-consuming aspect of restoration.

- Understanding the Interplay of Components: The governor is just one part of a larger system; friction in the drive mechanism, the condition of the motor itself, and even the alignment of the turntable can impact speed.

Beyond the mechanical challenges, corrosion can significantly hamper restoration efforts. Understanding how to effectively de-rust metal parts of an antique phonograph is an essential skill for any restorer. The presence of rust often signals a deeper issue, such as improper storage or inadequate lubrication, and addressing the root cause is as important as removing the surface corrosion.

Restoration Techniques – A Detailed Approach

Successful restoration involves a meticulous approach, and often, a significant amount of patience. It’s not simply about replacing worn parts; it's about understanding the original design intent and recreating it as closely as possible.

- Careful Disassembly: Thoroughly document the disassembly process, noting the position of all components. Photographs and detailed notes are invaluable. Consider using a labeling system for all parts to ensure correct reassembly.

- Cleaning and Inspection: Clean all parts thoroughly, removing old grease and debris. Inspection should reveal not just obvious wear, but also microscopic cracks or distortions. Use appropriate solvents and avoid harsh chemicals that could damage delicate materials.

- Lubrication: Apply appropriate lubricants to all moving parts. Use lubricants specifically designed for vintage mechanical devices; modern lubricants often contain additives that can damage delicate materials. Consider researching the original lubricant used by the manufacturer for optimal results.

- Adjustment: Carefully adjust the governor mechanism according to the manufacturer’s specifications (if available). This often involves trial and error and a keen ear for subtle changes in sound.

- Testing: Test the speed regulation system under various load conditions to ensure it is functioning correctly. This involves playing a range of recordings and observing the playback speed under different stresses on the mechanism.

- Long-Term Monitoring: After restoration, it’s important to periodically check the speed regulation system and re-lubricate as needed. Vintage mechanisms require ongoing maintenance to preserve their accuracy.

Advanced Considerations for Different Phonograph Types – A Model-Specific Guide

While the fundamental principles of speed regulation remain consistent, the specific implementation varies significantly across different phonograph models and manufacturers. Edison phonographs, known for their complex governor systems, require a particularly delicate touch during restoration. Victor models, with their worm drive mechanisms and flyweight compensation, present different challenges related to gear wear and lubrication. Later models utilizing synchronous motors, while generally more stable, still require careful adjustment to compensate for any fluctuations in power supply. For those encountering difficulties, further research into the specific model's technical documentation can provide invaluable insights into its unique operating characteristics.

Troubleshooting Common Issues – Practical Solutions

Even with meticulous restoration, unexpected issues can arise. A sticking governor arm, for instance, might require careful cleaning and lubrication. Excessive friction in the worm drive can be addressed by ensuring proper alignment and using the correct lubricant. The key is to systematically isolate the problem, test each component, and implement targeted solutions. It’s often helpful to compare the mechanism’s operation to known-good examples, if available. Remember that seemingly minor adjustments can have a significant impact on playback speed and fidelity.

Conclusion – Preserving a Piece of Audio History

Understanding the speed regulation system in antique phonographs is vital for preserving these remarkable machines. While these systems can be complex and challenging to restore, the satisfaction of bringing a vintage phonograph back to life is immensely rewarding. The ability to accurately reproduce the music of a bygone era is a testament to the ingenuity of early engineers and the skill of modern restorers. By embracing a methodical approach, researching the specific model, and seeking guidance when needed, anyone can contribute to the preservation of this important piece of audio history.