Restoring Phonograph Field Coils: Techniques for Optimal Sound and Performance

The field coil is a vital component of a phonograph’s electromagnetic drive system. It generates the magnetic field that moves the diaphragm, producing the sound we hear. Over time, these coils can deteriorate, leading to reduced volume, distortion, and overall poor performance. This guide explores the process of restoring phonograph field coils, covering cleaning, de-waxing, rewinding (when necessary), and insulation repair. We'll cover material selection, safety precautions, and techniques to ensure a reliable and powerful performance. This restoration can be complex, but with careful attention and the right techniques, you can breathe new life into your vintage phonograph. Understanding the historical context of these machines and their importance can also enrich the restoration experience – consider exploring the social impact of antique phonographs in early 20th century for a deeper appreciation.

Understanding the Field Coil

Before embarking on restoration, it’s essential to understand the field coil’s construction. Typically, it's a large coil of wire, often wrapped around a cardboard or wooden form. The wire itself is insulated, usually with varnish or cloth tape. This insulation protects the windings from short circuits and provides structural integrity. Deterioration commonly manifests as brittle insulation, loose windings, and wax build-up from old lubricant. The condition of the phonograph’s cabinet often mirrors the state of its internal components; should you be tackling a full restoration, be sure to consider the art of cabinet restoration alongside this coil repair.

Safety First

Working with electrical components requires caution. Always disconnect the phonograph from the power source before starting any repairs. Some older phonographs utilized high voltages within the field coil circuit – treat any component with respect. If you're unsure about any procedure, consult with a qualified technician. Using appropriate personal protective equipment, like gloves and eye protection, is strongly recommended.

Cleaning and De-Waxing

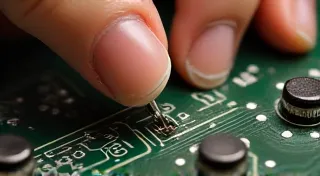

The first step in restoration is cleaning. Years of dust and wax can impede the coil’s performance. Start with gentle brushing to remove loose debris. Then, use a solvent designed for wax removal, such as mineral spirits or naphtha. Apply the solvent sparingly with cotton swabs, working carefully to avoid damaging the insulation. Multiple applications may be necessary. Always work in a well-ventilated area and wear appropriate respiratory protection. The careful removal of old lubricants is a key step in restoring the overall function – and even the sound - of the machine. It’s worth noting that proper needle replacement is also crucial for optimal sound quality; many resources exist to help with replacing the needle, a simple step that can yield a surprisingly large impact on performance.

Insulation Repair: Addressing Cracks and Damage

The insulation is the field coil’s Achilles heel. Cracking and flaking insulation can lead to short circuits and performance degradation. Minor cracks can sometimes be repaired with a specialized varnish or insulating compound. Apply the compound thinly and evenly, following the manufacturer's instructions. For more extensive damage, a more involved repair, such as applying thin strips of cloth tape or Mylar, may be required. These need to be carefully applied and varnished in place. The type of insulation used significantly impacts the performance and longevity of the coil. Ensuring compatibility with the phonograph’s overall design and operational environment is essential.

Rewinding: A Last Resort

Rewinding a field coil is a complex and time-consuming process best left to experienced restorers. It requires specialized equipment and a thorough understanding of the original winding pattern. Attempting it without the proper skills can easily damage the coil beyond repair. If rewinding is deemed necessary, carefully document the existing winding pattern before dismantling the coil. The wire gauge must match the original specification to avoid altering the coil’s impedance. Rewinding isn't just about replicating the coil's physical dimensions; it's about recreating its electrical characteristics. To do this correctly, a deep understanding of phonograph design, including the subtle interplay of mechanical and electrical components, is required.

Material Selection

When repairing or rewinding a field coil, using appropriate materials is crucial. The wire gauge should match the original, and the insulation must be compatible with the coil’s environment. Modern varnishes and insulating compounds are often superior to the originals, offering improved durability and electrical properties. However, always research the compatibility of any material before use. Understanding the various phonograph models is also beneficial during the material selection phase, as different models may have used different wire gauges or insulation types. Resources exist to help with identifying different phonograph models, ensuring you use the correct components for your restoration.

Beyond the Coil: The Broader Restoration

Restoring a phonograph field coil doesn't exist in a vacuum. It's often part of a larger restoration project that can encompass the cabinet, drive mechanism, and other components. Addressing these interconnected aspects ensures a holistic restoration, maximizing the phonograph’s performance and aesthetic appeal. The condition of the cabinet, for example, can be a good indicator of the overall health of the machine, hinting at potential issues with the internal components. A neglected cabinet often suggests a history of neglect, which may extend to the field coil and other critical parts.

Advanced Techniques for Insulation Repair

For severely damaged insulation, techniques beyond simple varnish application may be required. This could involve using thin strips of cloth tape or Mylar to reinforce the existing insulation. These strips must be carefully applied and varnished in place, ensuring they adhere properly and maintain the coil’s original geometry. Specialized heat-shrink tubing can also be used to encapsulate damaged sections of the coil, providing a layer of protection and preventing further deterioration. These advanced techniques require a high level of skill and experience, and should only be attempted by qualified restorers.

Troubleshooting Common Issues During Restoration

During the restoration process, several common issues can arise. These include difficulty removing old wax, brittle insulation that crumbles upon handling, and short circuits that are difficult to trace. Each of these issues requires a different approach to troubleshooting. For example, stubborn wax may require multiple applications of solvent and gentle scraping. Brittle insulation may require careful handling and the use of specialized adhesives. Short circuits may require meticulous inspection and the use of diagnostic equipment. Patience and attention to detail are essential for overcoming these challenges.

Testing and Final Steps

After completing the restoration, thoroughly test the field coil. Measure its resistance to ensure it’s within the expected range. Visually inspect the coil for any signs of shorts or insulation breakdown. Finally, reassemble the phonograph and test its sound quality. Minor adjustments to the drive mechanism may be necessary to optimize performance. Listening critically to the output is the final validation that the restoration has been successful. Subtle variations in tone or volume may indicate the need for further adjustments.

Conclusion

Restoring a phonograph field coil is a rewarding, albeit challenging, undertaking. By following these techniques and paying close attention to detail, you can revive the sound and performance of your vintage phonograph, ensuring its continued enjoyment for years to come. Remember to always prioritize safety and seek professional assistance when necessary. Understanding the rich history and cultural significance of these machines only enhances the restoration experience, and appreciating the craftsmanship involved deepens the connection to a bygone era. It’s a chance to preserve a piece of history and share its charm with future generations.