De-rusting Metal Parts of an Antique Phonograph

Rust is a common enemy of antique phonographs. Years of neglect, exposure to humidity, and even seemingly minor scratches can create an environment where iron and steel components corrode, diminishing their appearance and potentially impacting functionality. Thankfully, rust doesn't have to be a permanent fixture. This guide will explore several techniques for safely and effectively removing rust from the metal parts of your vintage phonograph, restoring their original luster and preserving its value.

Understanding the Severity of the Rust

Before you begin, it's crucial to assess the extent of the rust. Surface rust is relatively easy to remove and may only require mild techniques. Deep, pitted rust indicates a more significant issue, and may require more aggressive methods. Attempting to remove heavy rust quickly can damage the underlying metal, so patience is key. It's also worth considering the overall mechanics of your machine; understanding how the various components work together is crucial for proper restoration – sometimes a deep dive into the cartographer of silence—mapping the internal landscapes of record players—can offer valuable insight.

Gentle Methods for Surface Rust

For light surface rust, begin with the least abrasive methods first. These are less likely to damage the metal’s finish.

Vinegar Soak

Vinegar, particularly white vinegar, is a mild acid that can dissolve rust. Submerge the rusted part in vinegar for several hours or even overnight. This works best for smaller parts that can be easily removed. After soaking, scrub gently with a nylon brush or non-scratch scouring pad. Rinse thoroughly with clean water and dry completely to prevent new rust from forming.

Baking Soda Paste

Create a paste by mixing baking soda with water. Apply the paste to the rusted area and let it sit for about an hour. Scrub with a nylon brush or non-scratch pad. Rinse thoroughly and dry.

Lemon Juice and Salt

Similar to vinegar, lemon juice contains citric acid that can dissolve rust. Combine lemon juice with salt to create a mildly abrasive paste. Apply to the rusted area, let it sit, then scrub and rinse.

More Aggressive Methods for Moderate to Severe Rust

If gentle methods aren't effective, consider these more powerful approaches. Always test these on a small, inconspicuous area first to ensure they don’t damage the metal’s finish or any underlying paint. The shape and design of various phonograph components have evolved significantly over time, impacting their susceptibility to rust – studying the role of horns in early phonographs, for instance, can provide valuable context for understanding material selection and potential problem areas.

Commercial Rust Removers

Many commercial rust removers are available, often containing phosphoric acid or other active ingredients. Follow the manufacturer's instructions carefully, wearing appropriate safety gear (gloves, eye protection). These can be highly effective, but also potentially damaging if misused.

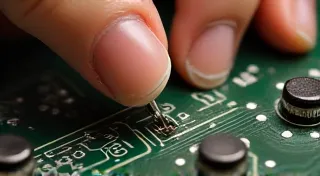

Wire Brush (with caution!)

A wire brush can be used to physically remove rust. However, it's highly abrasive and can scratch the metal if not used carefully. This is best suited for thicker metal parts and should be used with a light touch. Consider using a brass wire brush, which is softer than steel.

Electrolysis (Advanced)

Electrolysis is a more advanced rust removal technique that uses an electric current to remove rust. This method requires specific equipment and knowledge and is best left to experienced restorers. It's very effective at removing even stubborn rust without damaging the underlying metal.

The Importance of Replacement Parts and Components

In some cases, rust may be so extensive that removal is impractical or would compromise the structural integrity of the part. In such situations, sourcing replacement parts becomes necessary. Identifying the correct replacement can be challenging, particularly for rare or obscure models. Careful research and consultation with experienced phonograph collectors are essential. Understanding the original manufacturing processes and material specifications can aid in finding compatible replacements. Beyond the metal parts, even seemingly minor components like the needle play a vital role in the playback process - Replacing the needle is often crucial for restoring sound quality and preventing further damage.

Final Steps: Protecting the Restored Metal

Once the rust is removed, it's essential to protect the metal from future corrosion. This isn't just about aesthetics; it's about preserving the longevity of your antique phonograph.

Thorough Cleaning and Drying

Ensure the metal is completely clean and dry after rust removal. Any residue from the cleaning process can contribute to new rust formation. Consider using compressed air to ensure all traces of moisture are removed.

Applying Protective Coatings

Consider applying a protective coating, such as:

Different phonograph models employed various manufacturing techniques and materials, and a deep dive into the historical context surrounding your particular model will offer vital clues as to which type of finish would be most appropriate. Knowing your model—whether it’s a Victrola, a Gramophone, or something rarer—is crucial for successful restoration. Many resources exist online, as well as in print, to help in identifying different phonograph models and understanding their unique characteristics.

Restoring antique phonographs requires patience, care, and a willingness to learn. By following these techniques, taking precautions, and seeking expert advice when needed, you can successfully remove rust, preserve the original beauty, and ensure these beautiful pieces of history are enjoyed for generations to come.